ISO 16232 / VDA 19

Road Vehicles – Cleanliness of components of fluid circuits and systems.

In accordance with standard ISO 16232, the cleanliness inspection determines the contamination within components in which a fluid flows and refers to the creation of a procedure that includes both the gravimetric analysis and the particle analysis.

The entire volume of the fluid extracted is filtered through a test membrane and the deposited particles are analysed under a microscope. In order to determine the particle size, the contrast between the particle and the test membrane is used.

Standard ISO 16232 is a test that is usually requested for automotive sector-related components.

Its special nature is that it incorporates all the other standards concerning particle analysis issued prior to 2007. Standard ISO 16232 is the basic procedure from which subsequent, increasingly more elaborate analyses can be carried out, such as, the determination of the quality and quantity of particles via a microscopic count and the SEM EDS test.

Particulate matter, i.e. the surface dirt that has been washed away from the components, is separated from the wash liquor via filtration. The total amount of wash liquor used to extract the particulate matter from the samples in accordance with standard ISO 16232 is filtered through one or more membrane filters. The number of filters used depends on the mass of the contaminant in question.

This test may seem rather simple to non-experts.

Considering that these are very fine particles, it is easy to generate contaminations that cannot be attributed to the elements being tested, therefore it is advisable to have these tests carried out only in a test laboratory that has been accredited in accordance with standard ISO 17025.

This standard – ISO 16232 – describes how to carry out the test and report the relevant results. The technical specifications report the level of cleanliness required for a given component and it is necessary to ensure the repeatability and the significance of the test.

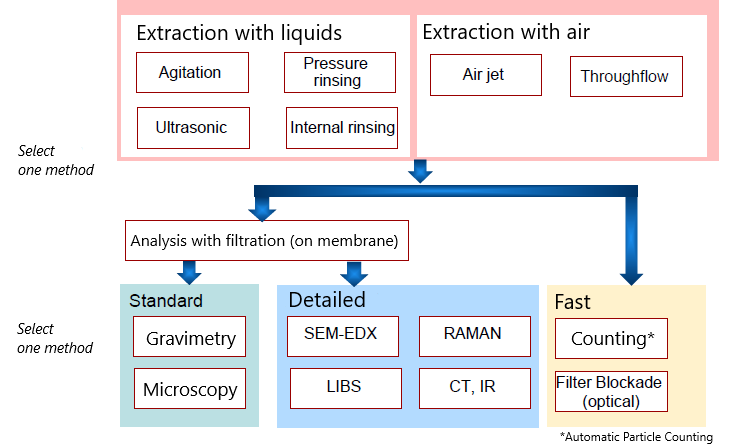

In order to be tested, the solid surface contamination must be removed from the component in question and dispersed in an appropriate test fluid. Generally speaking, in accordance with standard ISO 16232, the methods that can be used to disperse the contaminant in the test fluid are as follows:

Annex 1 – Description of the possible procedures to be adopted when the result of an inspection of cleanliness exceeds the permitted value specified in the cleanliness-related technical specifications.

Brief extract from standard ISO 16232

“Purpose of the standard:

In order to obtain the reliable performance of components and systems, it is necessary to check the quantity of particles introduced during the construction phase and the measurement of the particulate matter contaminants is at the basis of this test.

Based on a worldwide expansion and on the continuous development of problems relating to technical cleanliness, this document intends to:

-

Further improve the comparability of results from cleanliness inspections;

-

Include new techniques (relating to extraction and analyses);

-

Provide information on how to define the technical specifications of cleanliness and explain how to react when cleanliness limit values are exceeded.

Cleaning control principles

General information:

Since there are no components of the test of reference with a defined level of contamination in order to assess the efficiency of the procedures of extraction, the effect of the extraction conditions with regard to the cleanliness inspection must be studied on the basis of the following information:

-

Qualification of the extraction procedure (qualification test): the appropriate extraction procedure for a test component is determined by carrying out qualification tests. The qualification criteria are specified in this document. Their purpose is to guarantee that the greatest possible number of contaminated particles are removed from the test component. Finally, the results of the qualifications, the requirements and the parameters of the extraction procedure chosen are documented.

-

Blank level: the cleaner a test component is (or rather the lower the number of particles that is expected to be found during a cleanliness inspection), the greater the risk that the external contamination introduced into the test procedure falsifies the results. The Blank level is oriented at complying with the cleanliness requirements of the respective component being tested.

The cleanliness inspection consists of the following phases:

-

Supply of the test component;

-

Removal of particles from the test component (extraction);

-

Filtration of the particles (except with abbreviated testing);

-

Analysis of the particles;

-

Documentation of the inspection and results.

In order to carry out cleanliness inspections, the following are required: special equipment, suitable premises and expert, qualified personnel.

In order to be able to compare the results of the inspections the same test fluid, the same extraction procedure and the same test instrument parameter settings must be used.”

To download the standard: ISO 16232