Analysis laboratory

Oil analysis + Diagnosis + Corrective actions

The OilSafe internal oil test laboratory ensures:

-

Timeliness of the maintenance process (average time required to carry out tests: 1 day)

-

Prevention of machine downtime

-

Extension of the life cycle offluids, components and systems

The lab management programmes simplify the entire lubrication control procedure, by monitoring the key parameters of oil basing themselves on international standards, on technical specifications set by the main machinery manufacturers and providing the necessary know-how in order to obtain a better understanding of the status of the lubricants.

Therefore, OilSafe provides an all-round consultancy and analysis service. You take your sample of fluid and OilSafe will analyse it. By means of a technical report, the laboratory staff informs its customers of the results of the tests and, if necessary, any corrective actions and/or maintenance operations to be carried out.

The test laboratory acts provides active support to the OilSafe maintenance operations both during the preliminary plant set-up phases, such as the proper sizing of the flushing circuit and the on-board filters to be adopted, as well as in the subsequent commissioning phase, regarding the monitoring of the conditions of fluids and systems, such as the classification and relative contamination conditions. It is possible to resort to carrying out oil analyses in order to anticipate potential malfunctions and wear, by adopting a predictive maintenance strategy.

Field of application covered by the oil analysis test laboratory include:

-

Predictive maintenance of systems

-

Taking charge of new systems

-

Plant overhaul activities

OilSafe carries out laboratory tests on hydraulic fluids and lubricants, in accordance with national and international methods.

Main tests carried out

| Test | Standard of reference |

|---|---|

| TAN – Total Acid Number | ASTM D974 |

| TAN – Total Acid Number obtained by Potentiometric titration | ASTM D664 |

| Karl Fischer moisture content | ASTM D6304 |

| Kinematic viscosity at 40°C | ASTM D445 |

| Kinematic viscosity at 100°C | ASTM D445 |

| Viscosity index (Kinematic viscosity at 40°C+ 100°C) | ASTM D2270 |

| MPC patch test | OSMBR01 |

| RBOT/RPVOT oxidation stability test | ASTM D2272 |

| Demulsivity test 54/82°C | ASTM D1401 |

| FT-IR infrared test (spectrometry) | |

| PODS Particle Contamination test | ISO4406/NAS1638 |

| Rust prevention characteristics test | ASTM D665 |

| Air Release test at 50°C | ASTM D3427 |

| Foam test - seq. I | ASTM D892 |

| Foam test - seq. I-II-III | ASTM D892 |

| Colour test | ASTM D1500 |

| Flash point test – closed cup method | ASTM D93 |

| Flash point test – open cup method | ASTM D92 |

| Detection of elements test using plasmon + sulphur | ASTM D5185-18 |

| Density test | ASTM D4052-18 |

| Pour point test | ISO 3016:1994 |

| Total Base Number test | ASTM D2896 |

| Insoluble substances in n-pentane test | D893 |

| Aspect test | |

| Esem test | |

| Gravimetric analysis | Internal OilSafe Method |

| Morphological analysis of particulate matter on membrane – solid contaminant analysis on membrane | Internal OilSafe Method |

| Microscopic analysis without flushing | ISO16232 |

| Microscopic analysis with flushing | ISO16232 |

| Chlorine test | ASTM D7359-14a |

| Detection of elements with RDE spectrometer | ASTM D6595-17* |

| Ruler Test – detection of residual anti-oxidants | ASTM D6971 |

| Lasernet Particle Count test | ASTM D7596 |

How the OilSafe test laboratory works

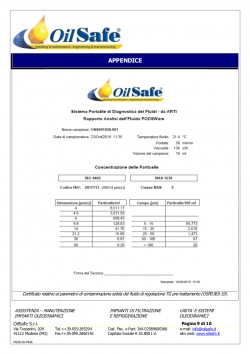

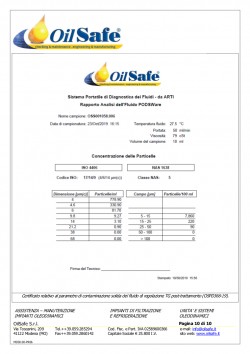

An example of an OilSafe consultancy service is given below. This refers to a report concerning to the oil analysis for the adjustment of a gas turbine: